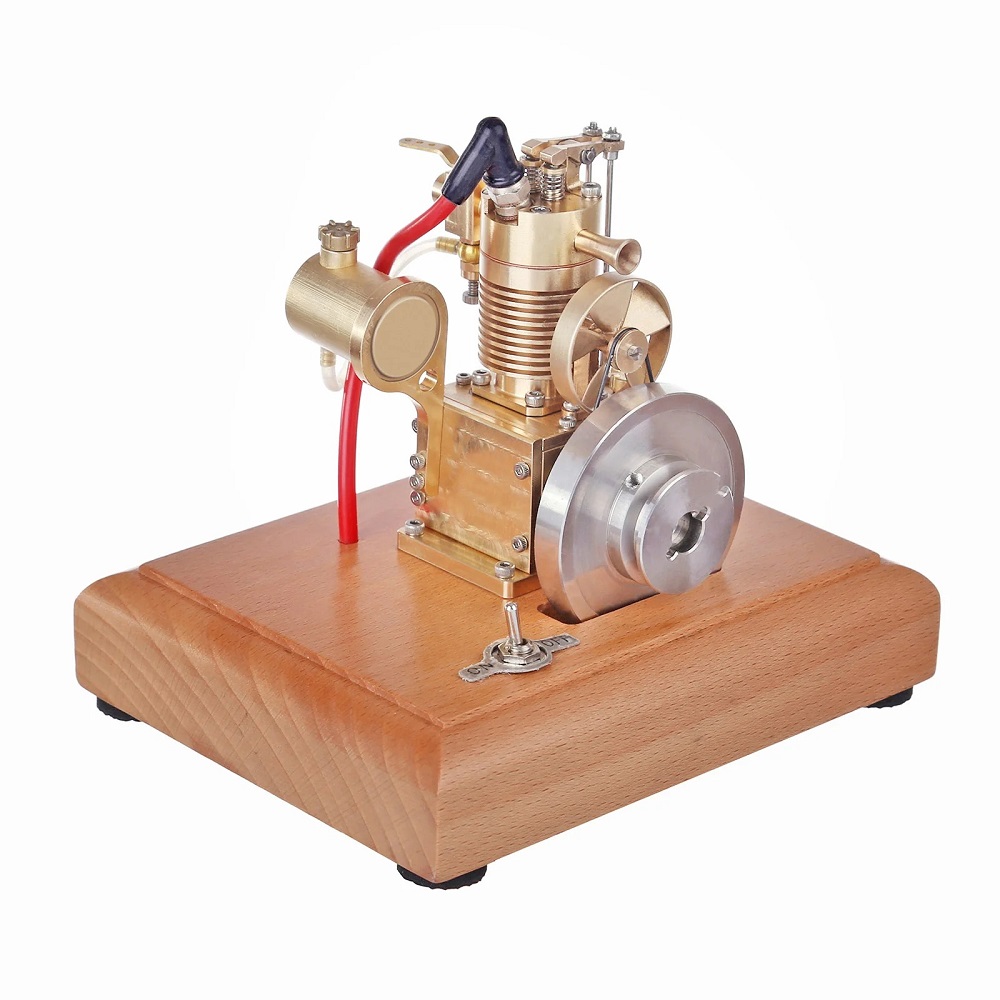

What is a One Cylinder Engine?

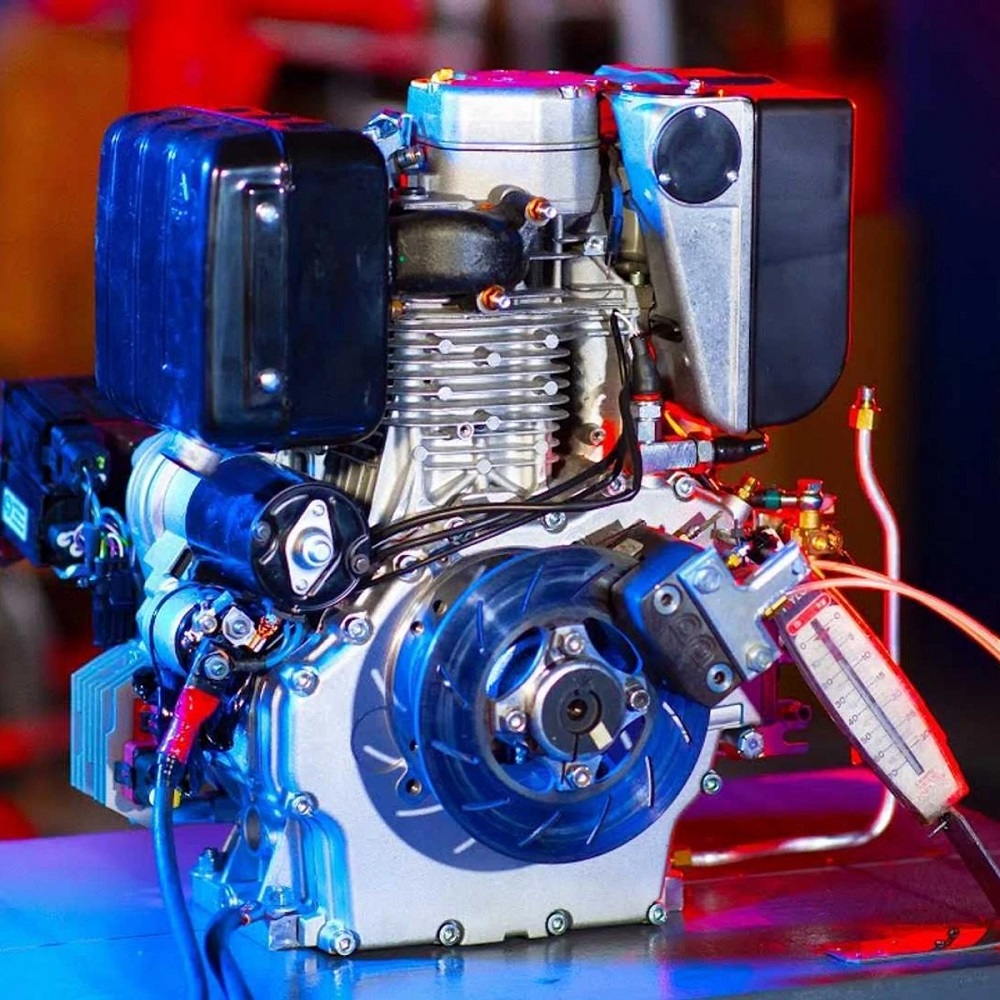

A one cylinder engine is a type of internal combustion engine. It has only one cylinder and one piston that drives its operations. This engine converts fuel energy into mechanical energy through ignition and combustion. The single cylinder setup makes the engine compact and lightweight.

One cylinder engines are often used in smaller machines due to their simple design. They are frequently found in motorcycles, lawn equipment, and small generators. Their simplicity makes them easy to maintain and cost-effective.

The engine operates by producing power through the combustion process inside its cylinder. Air and fuel mixture is ignited by a spark in the cylinder, pushing the piston. The piston movement turns the crankshaft, generating power.

These engines are especially suitable for basic applications that need low power output. However, they may not be ideal for larger vehicles or equipment requiring more power. Despite this, one cylinder engines remain popular for their compactness and ease of use across various industries.

History and Evolution of One Cylinder Engines

The one cylinder engine has a fascinating history. It emerged in the early development of engines. Early versions of internal combustion engines were single-cylinder due to simplicity. Engineers used basic designs to ignite fuel and generate power. These engines were compact, making them suitable for small devices.

Thomas Edison and other inventors influenced engine development. Their designs laid the foundation for modern engines. By the late 19th century, one cylinder engines gained popularity. They powered bicycles, motorcycles, and small equipment.

As technology improved, engines became more efficient. One cylinder engine designs evolved to enhance combustion. This increased their reliability and performance. The 20th century saw expanded applications. Lawn mowers, generators, and other machines widely used these engines.

Despite advancements, the one cylinder engine maintained its simplicity. Manufacturers embraced lightweight, durable designs for various applications. Innovations made them easier to maintain, extending their lifespan.

Throughout time, the one cylinder engine proved vital in industries. It supported agriculture, transportation, and household uses. Today, it remains relevant due to its cost-effectiveness and practicality.

How a One Cylinder Engine Works

A one cylinder engine operates through an internal combustion process to generate power. The process begins with the intake of an air-fuel mixture into the cylinder. This mixture is ignited by a spark plug, causing combustion.

During combustion, the fuel burns rapidly, creating high pressure inside the cylinder. This pressure pushes the piston downward, converting fuel energy into mechanical motion. The movement of the piston turns the crankshaft, a key component that transfers energy to drive external components, such as wheels or blades.

Key Phases of Engine Operation

- Intake Phase: The air-fuel mix enters the cylinder through the intake valve.

- Compression Phase: The piston compresses the mix to prepare it for combustion.

- Power Phase: Ignition occurs, producing pressure to move the piston.

- Exhaust Phase: Burnt gases exit through the exhaust valve.

These four phases repeat in every cycle, creating continuous power for machines. The simplicity of this design contributes to the cost-effectiveness and durability of one cylinder engines. Proper ignition timing and fuel-air ratio are crucial for efficient operation. Regular maintenance ensures smooth functioning and prevents breakdowns.

Advantages of One Cylinder

One cylinder engines offer many benefits that make them highly useful for various applications.

Compact and Lightweight Design

One cylinder engines have a simple design and fewer components. This makes them compact and lightweight. Their size allows for easy installation in small devices. They are ideal for machines with limited space.

Cost-Effectiveness

These engines are affordable to manufacture and repair. Maintenance is simple due to fewer moving parts. Operating costs are low, which attracts budget-conscious users.

Easy Maintenance

One cylinder engines have fewer parts that require regular upkeep. Troubleshooting and repairs are straightforward. Routine maintenance ensures longer engine life and reliability.

Fuel Efficiency

Single-cylinder engines consume less fuel compared to multi-cylinder engines. This is due to their simpler combustion mechanism. Users can save on fuel costs while lowering environmental impact.

Versatile Applications

One cylinder engines are used in motorcycles, lawn equipment, and small generators. Their adaptability makes them suitable for different industries. Their reliability in these applications is highly valued.

Durability and Longevity

Though compact, these engines are designed to be durable. They are built to withstand long hours of operation. When properly maintained, they perform effectively for years.

Reduced Noise Levels

One cylinder engines produce less noise compared to larger engines. This makes them ideal for quiet operation. Users benefit from reduced sound pollution during use.

In conclusion, the advantages of one cylinder engines include their cost, simplicity, and adaptability. Their practical features support widespread use across industries.

Common Applications of One Cylinder

One cylinder engines are versatile and used in many applications. Their compact design and simplicity make them suitable for a wide range of equipment and machinery. Here are some common applications of these engines:

Motorcycles and Scooters

One cylinder engines are common in motorcycles and scooters. Their lightweight design provides efficient power for smaller vehicles. They are ideal for navigating busy streets and narrow paths. Riders also appreciate their fuel efficiency and low maintenance requirements.

Lawn and Garden Equipment

These engines are widely used in lawn mowers, weed trimmers, and chainsaws. Their reliability and compactness make them perfect for outdoor tools. They handle tasks like cutting grass, trimming hedges, and chopping wood effectively.

Small Generators

One cylinder engines power small portable generators. These generators supply electricity during emergencies or at outdoor events. They are compact, making transportation and storage convenient.

Agricultural Tools

In farming, one cylinder engines drive tools like water pumps, tillers, and small tractors. Their durability is essential for long hours of operation. Farmers value their affordable operating costs and easy maintenance.

Construction Equipment

One cylinder engines are used in concrete mixers, compactors, and other construction tools. Their lightweight design ensures portability. The engines can sustain continuous use in demanding construction environments.

Recreational Vehicles

Small recreational vehicles like ATVs and go-karts use one cylinder engines. These engines provide reliable performance for leisure activities. They are also easy to repair and maintain.

Outboard Motors

Boats with small outboard motors often use one cylinder engines. These engines deliver the power needed for smooth navigation. Their simplicity makes them suitable for small watercraft.

Portable Machines

One cylinder engines power portable machines like pressure washers and air compressors. They are easy to handle and fuel-efficient. These features make them practical for various tasks.

Industrial Equipment

Certain small industrial machines use one cylinder engines. Examples include conveyor belts and small milling machines. The engines are dependable for industrial operations with low power demands.

In summary, one cylinder engines are highly adaptable and functional. Their application spans transportation, agriculture, construction, and recreation. This shows their enduring importance across many industries.

Challenges and Limitations of One Cylinder

Though one cylinder engines are practical and cost-effective, they have their challenges and limitations.

Limited Power Output

One cylinder engines produce less power compared to multi-cylinder engines. This makes them unsuitable for heavy machinery or large vehicles that require significant power.

Vibration Issues

The single-cylinder design can lead to increased vibrations. These vibrations can cause discomfort and faster wear and tear of the engine components over time.

Efficiency at Higher Speeds

One cylinder engines are less efficient at higher speeds. They perform best at low to moderate speeds, which limits their usage in high-performance applications.

Heat Dissipation

These engines tend to generate more heat in a single cylinder. This can cause overheating if the engine is not properly maintained or cooled effectively.

Noise and Smoothness

While smaller engines often produce less noise, intense vibrations can still lead to louder operations. Additionally, they lack the smooth operation of multi-cylinder engines due to power delivery inconsistency.

Limited Lifespan for High-Stress Applications

Using one cylinder engines in high-demand tasks can reduce their lifespan. They are not designed to handle continuous heavy usage over long periods.

Smaller Applications Only

They are not ideal for applications requiring high torque or continuous power. Their scope is restricted to smaller, simpler devices or tasks.

In summary, one cylinder engines are compact and affordable but carry restrictions. Understanding these limitations helps to choose the right engine for specific applications.

Maintenance Tips for One Cylinder Engines

Regular maintenance is crucial to keep one cylinder engines running smoothly and effectively. Proper care ensures longevity and reduces repair costs. Follow these tips to maintain your engine:

Check and Replace Oil Regularly

Engine oil lubricates moving parts and prevents wear. Check the oil level frequently. Change the oil based on the manufacturer’s recommendation. Use the correct grade of oil for optimal performance.

Clean or Replace Air Filters

Air filters prevent debris from entering the engine. Dirty filters reduce engine efficiency. Inspect air filters often and clean them as needed. Replace filters if they are damaged or overly clogged.

Keep Spark Plug Clean and Functional

The spark plug ignites the fuel-air mixture. A dirty spark plug lowers performance. Clean the spark plug periodically to remove carbon build-up. Replace it if worn or damaged.

Inspect and Tighten Bolts

Loose bolts can cause engine vibrations and damage. Check all bolts regularly. Tighten them securely to prevent issues during operation.

Monitor Fuel Quality

Use clean and high-quality fuel to avoid engine damage. Drain old fuel if the engine isn’t used for long periods. This prevents clogging and ensures efficient combustion.

Check Cooling System

Overheating can harm your engine. Make sure cooling components like fans and radiators function well. Clean them regularly to avoid blockages.

Perform Routine Inspection

Regularly inspect components, including belts, hoses, and seals. Replace worn or damaged parts immediately. This prevents sudden breakdowns and costly repairs.

Store Properly

Store engines in a dry, clean area to prevent rust. Drain fuel before long-term storage. Cover the engine to protect it from dust and moisture.

Follow Manufacturer’s Guidelines

Always adhere to the manufacturer’s maintenance schedule. Use recommended parts and follow instructions for repair and care. This maximizes engine efficiency and lifespan.

By following these maintenance tips, you can extend your one cylinder engine’s life and improve its performance. Regular upkeep guarantees smooth operation and reduces downtime.

Future Prospects and Innovations in One Cylinder Engine Technology

The future of one cylinder engines looks promising with ongoing advancements and technological innovations. Engineers aim to enhance efficiency, reduce emissions, and improve overall performance. Here are some notable future prospects and innovations:

Enhanced Fuel Efficiency

Manufacturers are focusing on improving fuel efficiency. Advanced combustion techniques and optimized fuel-air ratios are being developed. These innovations can reduce fuel consumption and emissions, making one cylinder engines more eco-friendly.

Adoption of Hybrid Technology

Combining one cylinder engines with electric power systems can create hybrid engines. This integration offers better fuel efficiency and lower carbon emissions. Hybrid one cylinder engines could be ideal for small vehicles and portable machines.

Use of Advanced Materials

Innovative materials are being used to reduce weight and improve durability. Lightweight alloys and carbon fiber materials are being incorporated into engine design. This ensures better performance and increases the engine’s lifespan.

Electronic Fuel Injection Systems

Traditional carburetors are being replaced with advanced electronic fuel injection (EFI) systems. EFI systems offer precise fuel delivery for combustion, enhancing power output and reducing wastage.

Improved Cooling Systems

New cooling technologies are being designed to prevent overheating. These systems maintain optimal operating temperatures, prolonging the engine’s life and performance.

Reduced Environmental Impact

Engineers continue working to make one cylinder engines more environmentally friendly. Developments include using alternative fuels like biofuels and enhancing exhaust systems to meet strict emission standards.

Noise and Vibration Reduction

Technological advancements are minimizing noise and vibration in one cylinder engine. This leads to quieter and smoother operation, making the engines more appealing for various applications.

Introduction of Smart Engine Technology

Smart technologies are also being integrated into one cylinder engine. Sensors and software monitor performance in real time. They provide alerts for maintenance and optimize engine operations efficiently.

Broader Applications

Future advancements will expand the range of applications for one cylinder engines. These engines may power more types of devices, especially in remote or developing areas.

In conclusion, innovation in one cylinder engine technology focuses on efficiency, sustainability, and versatility. These developments ensure their relevance in an ever-changing technological landscape.

Leave a Reply