Introduction to High Cylinder Engines

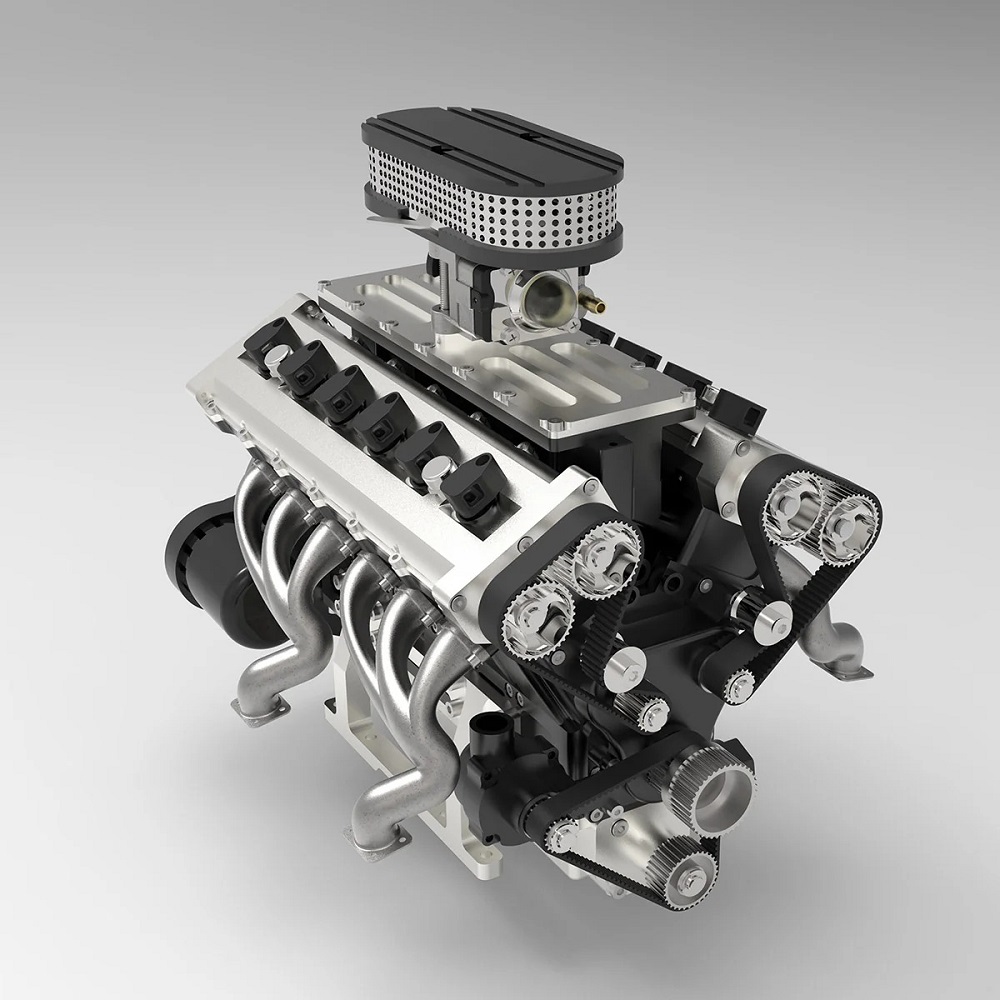

Highest cylinder engine is marvels of engineering. They feature multiple cylinders working together to generate immense power. These engines are designed to enhance performance, efficiency, and reliability in various applications.

Cylinder count significantly impacts an engine’s smoothness and power delivery. More cylinders allow for better power distribution and balanced operation. This is why such engines are found in high-performance cars, motorcycles, and even aircraft.

These engines are typically larger and more complex than standard engines. Each cylinder adds to the engine’s total displacement, improving its ability to produce power. However, managing many cylinders requires advanced technology and precision engineering.

Some of the most powerful engines in the world utilize a high number of cylinders. For example, the Bugatti Chiron’s W16 engine uses 16 cylinders to deliver unprecedented power. Aircraft engines and race car engines also push the boundaries of multi-cylinder designs.

In summary, high-cylinder engines demonstrate remarkable technological achievements. They combine power, efficiency, and cutting-edge engineering to meet demanding performance requirements.

History and Evolution of Multi-Cylinder Engines

The history of multi-cylinder engines dates back to the late 19th century. Early engines typically had only one or two cylinders. As technology advanced, engineers realized the benefits of adding more cylinders. This innovation led to smoother operation and improved power output.

In the early 1900s, car manufacturers began experimenting with four-cylinder and six-cylinder engines. These engines allowed vehicles to achieve faster speeds and better performance. Shortly after, manufacturers like Ford and Cadillac introduced innovative V8 engines. This marked a major milestone in automotive engine design.

In the mid-20th century, multi-cylinder engines became more prominent in different industries. Aircrafts started using radial and inline engines with multiple cylinders for increased power and reliability. Racing cars also adopted engines with as many as 12 cylinders to maximize performance.

By the late 20th century, advances in engineering made high-cylinder engines more efficient and precise. The development of the Bugatti Veyron’s W16 engine and other groundbreaking designs showcased the potential of these engines. This era also saw better materials, computer-aided design, and advanced manufacturing processes, pushing the limits of multi-cylinder engines further.

Today, high-cylinder engines are used in luxury cars, racing vehicles, aircraft, and other specialized applications. They continue to evolve, with engineers focusing on improving efficiency, sustainability, and overall performance. The journey of multi-cylinder engines reflects the progress of technology and the human quest for innovation.

Benefits of High Cylinder Engines

Highest cylinder engine offer several remarkable benefits, making them essential in high-performance machinery. Their advantages are rooted in power output, efficiency, smoothness, and reliability.

Higher Power Output

- High cylinder engine generate more power by combining the output from multiple cylinders.

- Each cylinder contributes to the overall displacement, allowing higher horsepower.

- This makes them suitable for vehicles like supercars and aircraft that demand exceptional power.

Smoother Performance

- More cylinders ensure a smoother distribution of power during operation.

- High cylinder counts reduce vibrations, improving the driving or operating experience.

- This smooth operation enhances stability and control, especially in high-speed conditions.

Enhanced Durability and Reliability

- The balanced operation of highest cylinder engine reduces wear and tear.

- Each cylinder shares the workload, extending the engine’s lifespan.

- These engines are often built with cutting-edge materials, ensuring durability under extreme conditions.

Improved Acceleration and Efficiency

- More cylinders enhance throttle response and acceleration speed.

- High cylinder engines optimize performance and deliver better fuel combustion.

- The even distribution of power improves overall energy efficiency.

Versatility Across Applications

- High cylinder engines excel in various applications, from luxury cars to aerospace technology.

- Their power and performance make them ideal for racing and heavy machinery.

In conclusion, highest cylinder engine merge power with precision. They meet demanding requirements across industries by delivering unmatched performance, smoothness, and reliability.

Examples of Record-Breaking High Cylinder Engines

High cylinder engines have set incredible records in automotive and aviation history. These engines showcase engineering excellence and raw power.

Bugatti Chiron’s W16 Engine

- The Bugatti Chiron features a W16 engine with 16 cylinders.

- This engine generates an unmatched 1,500 horsepower.

- It enables the car to reach speeds over 260 mph.

Rolls-Royce Merlin V12 Engine

- Rolls-Royce developed the Merlin V12 engine for aircraft during World War II.

- It powered iconic planes like the Spitfire and Mustang.

- The engine provided about 1,600 horsepower, ensuring exemplary aviation performance.

Detroit Diesel 24V-71

- This engine has an astounding 24 cylinders.

- It is mainly used in industrial equipment and marine vessels.

- Its high torque output meets demanding heavy-duty requirements.

Fiat AS.6 Engine

- The Fiat AS.6 aircraft engine features 24 cylinders.

- It holds records for speed in aviation history.

- With over 3,000 horsepower, it demonstrates outstanding engineering.

Napier Sabre H24 Engine

- The Napier Sabre utilizes an innovative H24 cylinder design.

- It powered military aircraft during the mid-20th century.

- This engine produced approximately 2,500 horsepower for high-speed planes.

Chevrolet V16 Experimental Engine

- Chevrolet explored V16 engines for experimental purposes.

- These engines achieved high power outputs for supercars.

- Though rare, they symbolize groundbreaking potential.

Record-breaking engines inspire innovation and showcase human ingenuity. Their achievements underline the importance of engineering advancements in meeting extreme power demands.

Applications of High Cylinder Engines in Various Industries

High cylinder engines are versatile and find usage in a range of industries. Their power, efficiency, and reliability make them ideal for demanding applications.

Automotive Industry

- High cylinder engines power supercars and luxury vehicles.

- Bugatti and Ferrari use these engines for top performance.

- They deliver smooth acceleration and unparalleled driving experiences.

Aviation Sector

- Aircraft engines often rely on multi-cylinder designs for high power.

- Rolls-Royce Merlin V12 and radial engines are prime examples.

- They enable planes to achieve long-range flights and enhanced safety.

Heavy Machinery and Industrial Equipment

- These engines are used in heavy-duty vehicles and marine vessels.

- Detroit Diesel 24-cylinder engines handle extreme workloads.

- They ensure reliability for continuous operation in tough environments.

Racing Industry

- Race cars use engines with up to 12 cylinders for maximum speed.

- The even power distribution boosts control during high-speed races.

- These engines push the limits of performance and engineering.

Marine Applications

- Ships and marine vessels use high cylinder engines for power and endurance.

- Multi-cylinder designs offer stability during long voyages.

- Industrial marine engines are built for efficiency under heavy conditions.

High cylinder engines adapt to various fields, showcasing engineering excellence. Their applications support innovation and technological growth across industries.

Challenges and Limitations of High Cylinder Engines

High cylinder engines present remarkable advantages but face significant challenges and limitations.

Complexity in Design and Manufacturing

- High cylinder engines are intricate, requiring advanced engineering and technology.

- Precision manufacturing is critical to ensure efficient and reliable operation.

- The addition of cylinders increases the complexity of assembly and maintenance.

High Costs

- These engines are expensive to design, build, and maintain.

- High-quality materials and skilled labor drive up production costs.

- Repair and replacement of parts can also be costly.

Increased Space Requirements

- High cylinder engines occupy more physical space due to their design.

- Larger size makes them unsuitable for compact vehicles or machinery.

Weight Concerns

- Additional cylinders lead to more weight.

- Excess weight impacts fuel efficiency and handling, especially in smaller vehicles.

Fuel Consumption

- High cylinder engines consume more fuel due to their greater power outputs.

- They are less eco-friendly compared to smaller, fuel-efficient engines.

Heat Generation and Cooling Challenges

- More cylinders produce more heat during operation.

- Efficient cooling systems are needed, adding complexity and cost.

Limited Applications

- High cylinder engines are suited primarily for niche applications.

- They are used in supercars, aircraft, or heavy machinery, not everyday vehicles.

Difficulty in Repairs

- Maintenance requires specialized knowledge and tools.

- Repairing complex components can be time-consuming and expensive.

Despite their power and performance, high cylinder engines face limitations in practicality and cost-efficiency. These challenges are critical for their widespread application.

Future Trends in High Cylinder Engine Development

The field of high cylinder engines continues to evolve, driven by technological advancements and innovation. Engineers focus on creating engines that offer higher performance while addressing current limitations.

Lightweight Materials

- Future engines will use lighter materials like carbon fiber and aluminum.

- Reduced weight improves efficiency and minimizes fuel consumption.

- Lighter engines allow better performance without compromising structural integrity.

Hybrid Technology

- Combining high cylinder engines with electric power is becoming a trend.

- Hybrid systems improve sustainability and reduce environmental impact.

- Electric motors will complement cylinders for optimized performance.

Advanced Cooling Systems

- New cooling technologies aim to handle increased heat in high cylinder engines.

- Improved designs ensure optimal temperature management during high-performance tasks.

- Enhanced cooling systems reduce the risk of overheating damage.

Smaller and More Compact Designs

- Engineers focus on reducing engine size without sacrificing power.

- Compact designs will fit into a wider variety of vehicles and machinery.

- This trend addresses space and weight concerns.

AI and Machine Learning Integration

- Artificial intelligence will assist in monitoring engine performance.

- Predictive maintenance reduces downtime and improves reliability.

- AI helps optimize fuel combustion and energy efficiency.

Sustainability and Green Innovations

- Manufacturers aim to reduce carbon emissions from high cylinder engines.

- Enhanced fuel efficiency aligns with eco-friendly regulations.

- Renewable energy adaptation may bring revolutionary changes to engine design.

3D Printing and Manufacturing

- 3D printing enables precise construction of engine components.

- It lowers production costs while improving customization.

- Faster manufacturing speeds will boost innovation.

Future high cylinder engines aim to balance power, efficiency, and sustainability. Engineers continually push boundaries to meet evolving industry needs.

Innovations and Engineering Behind Multi-Cylinder Engines

High cylinder engines benefit from continuous technological improvements and engineering innovations. These advancements enhance performance, reliability, and efficiency, pushing the boundaries of what’s possible in engine design.

Advanced Material Usage

- Lightweight materials like titanium and aluminum improve engine efficiency and reduce weight.

- Composite materials enhance durability under extreme stress and temperature conditions.

- Engine components are now designed for better strength-to-weight ratios.

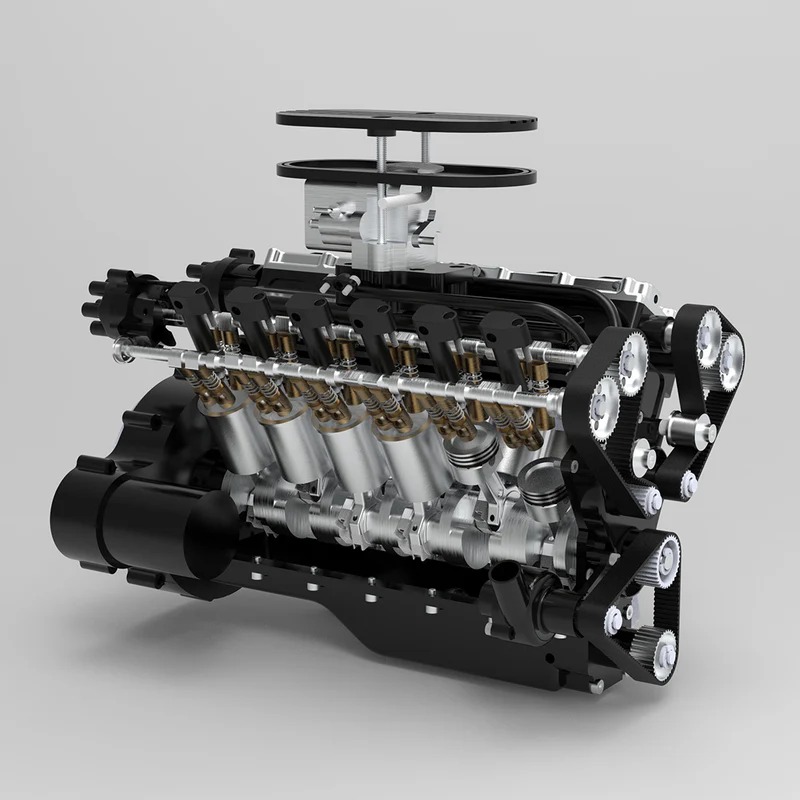

Precision Manufacturing Techniques

- CNC machining is used for accurate component fabrication.

- Automation ensures precision and consistency in assembling intricate engine parts.

- Laser welding improves the structural integrity and reliability of connections.

Improved Combustion Efficiency

- Innovations focus on optimizing air-fuel mixture for better combustion.

- Direct fuel injection enhances energy utilization and reduces waste.

- Turbocharging and supercharging increase power without needing extra cylinders.

Sophisticated Engine Design

- Engineers use computer simulations to create more compact and efficient multi-cylinder engines.

- Modular designs allow for customization based on specific industry requirements.

- Improved crankshaft and camshaft designs ensure smoother power delivery.

Enhanced Cooling Systems

- Advanced cooling techniques prevent overheating in high-performance engines.

- Liquid and air-cooling systems work together for effective temperature control.

- Engine layouts are optimized for better heat dissipation.

Noise and Vibration Reduction

- Innovations in design reduce engine noise and vibrations.

- Balancer shafts and improved mounts enhance driving comfort.

- Noise dampening materials contribute to quieter operation.

Electronics and Control Systems

- Modern engines use electronic control units (ECUs) for optimized performance.

- Sensors monitor engine parameters like temperature, pressure, and speed.

- Real-time adjustments improve fuel efficiency and power output.

Sustainable Engineering Practices

- Eco-friendly designs aim to lower emissions and improve fuel economy.

- Renewable energy sources are explored for powering high-cylinder engines.

- 3D-printed components minimize waste and reduce production costs.

The engineering innovations behind high-cylinder engines highlight human ingenuity and technical skill. These advancements contribute to their powerful performance and diverse applications.

Embracing the Power of High Cylinder Engines

A Commitment to Performance

High cylinder engines, such as V12 or W16 models, represent the pinnacle of automotive engineering. Offering exceptional power, smooth operation, and innovative design, these engines appeal to drivers looking for performance. Maintaining these engines requires dedication and care, ensuring they continue to operate optimally. By understanding the features and care options, drivers can embrace the power and excitement these engines offer.

Enhancing the Driving Experience

Owning a vehicle with a highest cylinder engine can enhance your overall driving experience. The thrill of acceleration, the smoothness of operation, and the impressive power output create an exhilarating atmosphere on the road. Whether you drive for leisure or work, experiencing the capabilities of a high cylinder engine can deepen your appreciation for automotive engineering.

Ready for the Road Ahead

Armed with insights about highest cylinder engine, you are now prepared to appreciate their significance in the automotive world. Embrace the advancements, understanding, and technology behind these powerful engines. With the right care and attention, your highest cylinder engine will provide countless memorable moments on the road. Get ready to enjoy every ride, knowing you are experiencing the best engineering has to offer!

Leave a Reply