What is a Single Cylinder Engine?

A single cylinder engine is an internal combustion engine. It operates with one cylinder and piston. This engine is designed to convert fuel into mechanical energy. The cylinder houses the piston, which moves up and down during combustion.

In single cylinder engines, fuel and air mix inside the combustion chamber. A spark ignites this mixture, producing power to rotate the crankshaft. The crankshaft transfers energy to power various devices or vehicles.

This engine type is simple in design. It often features compact size and reduced weight. These engines are widely used due to their affordability and efficiency.

Single cylinder engines come in 2-stroke and 4-stroke varieties. The choice depends on application needs. Both options differ in power delivery and fuel economy. Despite their simplicity, they offer reliable performance for many applications.

These engines are commonly used in motorcycles, lawn mowers, and generators. Their basic design makes them easier to maintain and repair. As a foundation, understanding single cylinder engines helps in assessing their uses and benefits.

Advantages of Single Cylinder

Single cylinder engines offer several advantages that make them suitable for various applications. Their simple design and compact size are key benefits.

1. Cost-Effective

Single cylinder engines are less expensive compared to multi-cylinder engines. Manufacturing fewer parts reduces the overall cost. This makes them budget-friendly for buyers.

2. Lightweight and Compact

These engines are lightweight due to simplified construction. Their compact design makes them ideal for small devices. Lightweight engines reduce total equipment weight.

3. Easy Maintenance

Fewer components lead to easier and faster maintenance. Repairs are straightforward for these engines. This simplicity is helpful for inexperienced users.

4. High Fuel Efficiency

Single cylinder engines deliver better fuel efficiency for certain tasks. They consume less fuel while providing sufficient power. This helps users save on fuel costs in the long run.

5. Great for Low Power Needs

These engines perform well for applications requiring low power. Examples include lawn mowers, motorcycles, and generators. Their performance remains reliable under such conditions.

6. Durable and Reliable

Single cylinder engines are durable due to their simple build. Their reliability makes them suitable for repeated use. Many users choose them for dependable operation over time.

7. Environmentally Friendly Potential

Their efficient fuel consumption may produce fewer emissions compared to other engine types. This can contribute to environmental protection in specific usage scenarios.

By understanding these advantages, individuals can decide if a single cylinder engine meets their needs. It is a practical choice for many everyday applications.

Common Applications of Single Cylinder

Single cylinder engines are versatile and have many uses across different industries and devices. Their compact size, simplicity, and cost-efficiency make them ideal for various applications.

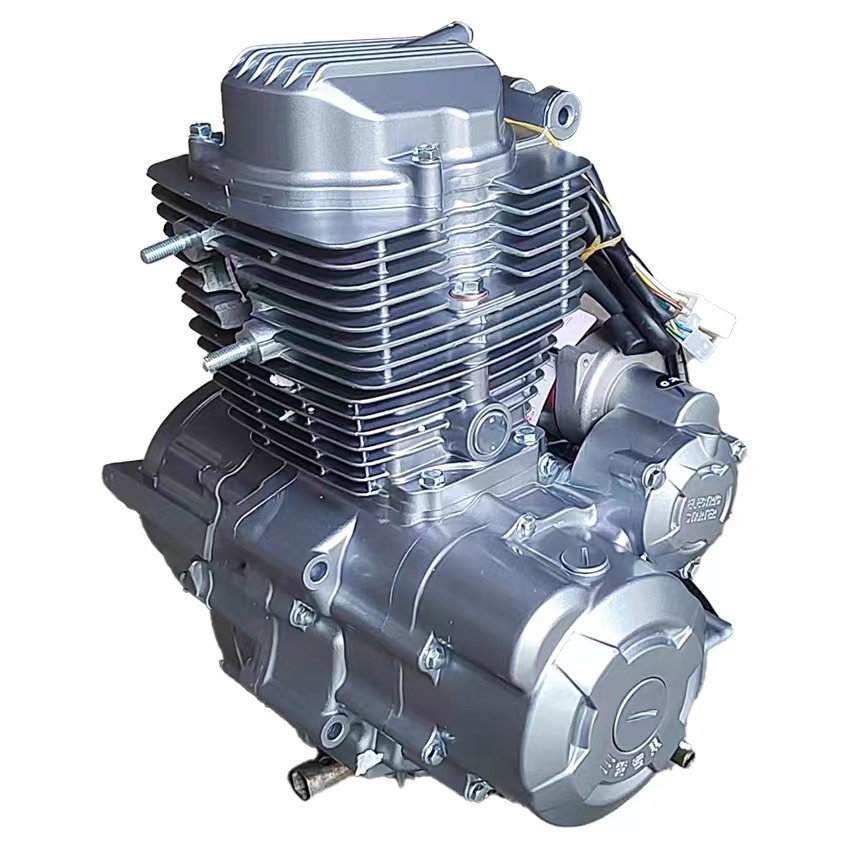

1. Motorcycles

Single cylinder engines are popular in motorcycles. They offer good power for smaller bikes. Their lightweight design makes motorcycles easier to handle. Fuel efficiency ensures riders enjoy longer trips without frequent refueling.

2. Lawn Mowers

These engines power most lawn mowers. They are reliable and provide sufficient torque for cutting grass. Their small size fits well in lawn mower designs. Easy maintenance is convenient for homeowners.

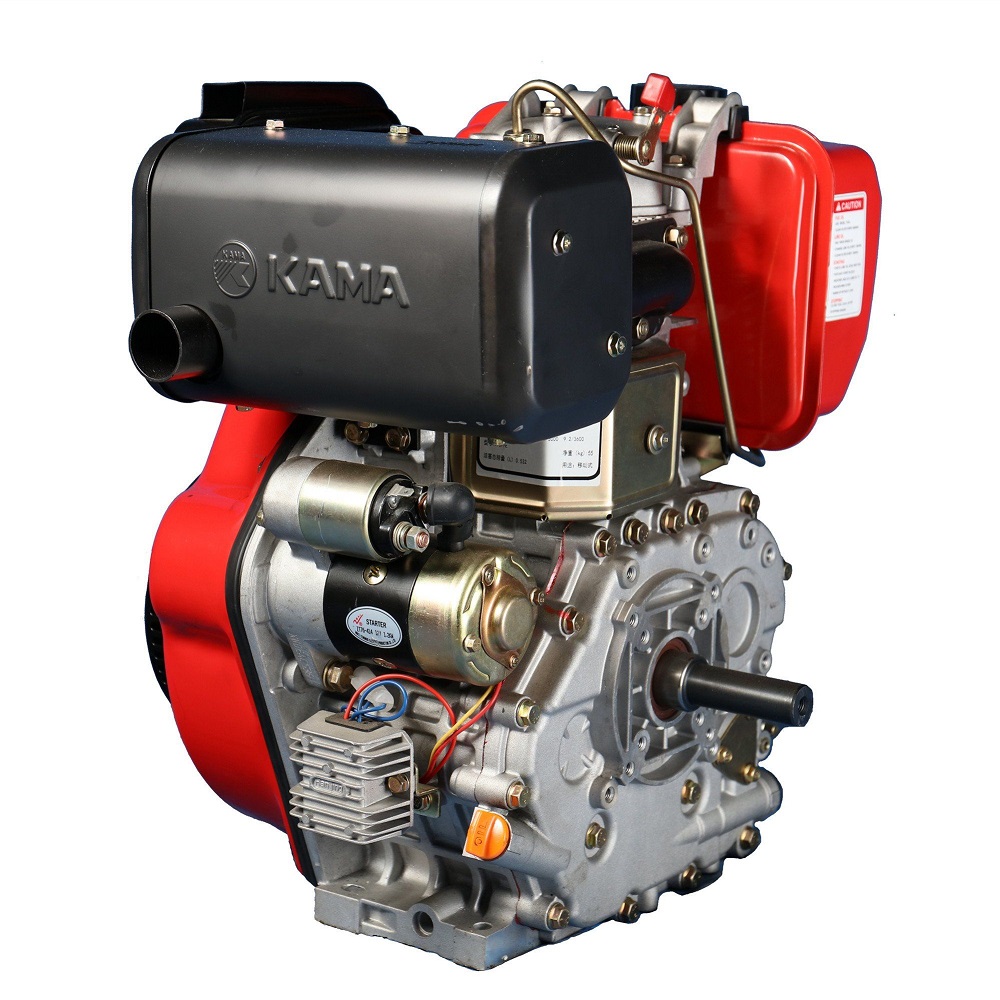

3. Generators

Single cylinder engines are widely used in portable generators. They deliver enough energy for basic electricity needs. Compact engines make storage and transport simple. They are a favorite choice during power outages.

4. Agricultural Equipment

Small machines like tillers and mini-tractors use single cylinder engines. They are dependable for small farming tasks. These engines are easy to repair, which benefits farmers in rural areas.

5. Pumps

Single cylinder engines are used in water pumps. They provide steady power for pumping systems. Their affordability makes them accessible for irrigation and household pumping needs.

6. Recreational Vehicles

ATVs and go-karts often utilize single cylinder engines. They provide adequate power for fun rides. Their lightweight nature adds to thrill and maneuverability.

7. Marine Equipment

Small boats and jet skis use these engines. They are efficient for limited marine activities. Engine simplicity allows easy handling and lower long-term costs.

8. Construction Equipment

Compact single cylinder engines power small construction tools like concrete mixers. They ensure reliable performance in demanding conditions. Their durability supports frequent use at work sites.

Single cylinder engines are practical for devices that require affordable, lightweight, and efficient engines. Their flexibility in usage makes them a great choice for many everyday tasks.

Key Components of a Single Cylinder

A single cylinder engine has a simple yet functional design. It consists of several key components that work together to convert fuel into mechanical energy. Below are the main parts:

1. Cylinder

The cylinder is the core of the engine where combustion occurs. It houses the piston and guides its movement. Its size determines the engine’s power and displacement.

2. Piston

The piston moves up and down inside the cylinder. This motion is crucial for compressing the air-fuel mixture and transmitting force to the crankshaft. Pistons are usually made from lightweight, heat-resistant materials.

3. Cylinder Head

The cylinder head closes off the top of the cylinder. It contains valves, spark plugs, and sometimes the fuel injector. It allows for the proper entry of air-fuel mixtures and the exit of exhaust gases.

4. Crankshaft

The crankshaft converts the piston’s linear motion into rotational motion. This rotational energy powers the connected equipment or vehicle. It is a key component for energy transfer.

5. Connecting Rod

The connecting rod links the piston to the crankshaft. It transmits the power from the piston to the crankshaft. Its durability ensures smooth energy transfer.

6. Valves

Engines have two main valves: the intake and exhaust valves. The intake valve allows air and fuel into the cylinder. The exhaust valve allows burnt gases to exit after combustion.

7. Spark Plug

The spark plug ignites the air-fuel mixture inside the cylinder. It generates the spark required for combustion to occur. This spark initiates power production.

8. Flywheel

The flywheel maintains engine balance and regulates speed fluctuations. It stores rotational energy produced by the engine. This component helps ensure smooth operation.

9. Camshaft

The camshaft controls the opening and closing of the engine’s valves. It ensures proper timing for air intake and exhaust expulsion. This timing is crucial for efficient combustion.

10. Carburetor/Fuel Injector

The carburetor or fuel injector manages the mixing of fuel and air in the proper ratio. A carburetor uses air pressure changes, while a fuel injector sprays fuel directly into the cylinder.

Each of these components is essential for the smooth operation of a single cylinder engine. Understanding their roles is crucial for maintaining and repairing these engines. Their simple and efficient design makes maintenance relatively easy for users.

How Single Cylinder Work

Single cylinder engines work by converting fuel into mechanical energy. Their operation involves several steps that take place within the cylinder. Here’s a simplified explanation of how they function:

1. Intake Stroke

The intake valve opens to allow air and fuel into the cylinder. The piston moves down, creating space for the mixture.

2. Compression Stroke

The piston moves up to compress the air-fuel mixture. Compression increases energy for ignition.

3. Ignition

The spark plug creates a spark to ignite the compressed air-fuel mixture. Combustion begins.

4. Power Stroke

The ignited mixture expands rapidly, pushing the piston downward. This generates mechanical energy.

5. Exhaust Stroke

The exhaust valve opens to expel burnt gases. The piston moves up, clearing the cylinder.

These cycles repeat to keep the engine running. The crankshaft converts the piston’s energy into rotational motion. This motion powers equipment or vehicles.

Single cylinder engine differ by stroke type: 2-stroke or 4-stroke. A 2-stroke engine completes all processes in two piston movements. A 4-stroke engine requires four piston movements for the same processes.

Understanding the operation of single cylinder engines highlights their simplicity and effectiveness.

Maintenance Tips for Single Cylinder

Proper maintenance ensures the longevity and performance of single cylinder engines. Here are key tips:

1. Regular Oil Changes

Change the engine oil regularly. Clean oil reduces friction and prevents damage. Follow manufacturer recommendations for intervals.

2. Inspect and Clean Air Filters

Dirty air filters affect engine efficiency. Check them often and clean or replace as needed. This ensures proper airflow to the engine.

3. Check Spark Plug Condition

Inspect spark plugs for wear or buildup. Replace worn plugs to maintain smooth ignition. Clean buildup for better performance.

4. Tighten Loose Bolts and Nuts

Vibrations can loosen bolts over time. Secure all components during maintenance checks. Prevents mechanical failures.

5. Clean the Carburetor or Fuel Injector

Carburetors or fuel injectors may clog with dirt. Regular cleaning ensures optimal air-fuel mixing. Use a cleaning solution suitable for the engine.

6. Monitor Engine Cooling System

Overheating can harm engine parts. Check cooling systems like air vents or water jackets. Ensure they’re functioning properly.

7. Examine Valves and Adjust if Needed

Inspect intake and exhaust valves for proper operation. Adjust them based on engine manual guidelines. Prevents combustion issues.

8. Lubricate Moving Parts

Apply grease or oil to moving components. This reduces wear and tear. Focus on areas prone to friction.

9. Maintain Fuel Quality

Use clean, high-quality fuel to avoid buildup or clogs. Drain old fuel if engine sits idle for long periods.

10. Conduct Regular Engine Inspections

Perform visual checks for unusual leaks, noises, or damage. Address issues early to avoid costly repairs.

Following these maintenance tips helps keep single cylinder engine running smoothly. Consistent care ensures reliability and extends their lifespan.

Comparison Between Single Cylinder and Multi-cylinder Engines

Single cylinder and multi-cylinder engines differ in design and performance. Understanding their differences helps in selecting the right engine for your needs.

1. Design and Complexity

Single cylinder engines have simple designs with fewer parts. Multi-cylinder engines are complex with multiple cylinders. More components typically mean increased maintenance requirements in multi-cylinder engines.

2. Performance

Single cylinder engines deliver adequate power for low-demand tasks. Multi-cylinder engines provide higher performance and are ideal for heavy machinery.

3. Cost

Single cylinder engines are more affordable due to simpler designs and fewer parts. Multi-cylinder engines are costlier because of their complexity and manufacturing processes.

4. Fuel Efficiency

Single cylinder engines use less fuel for low-power tasks. Multi-cylinder engines consume more fuel but perform better for higher loads.

5. Maintenance

Single cylinder engines are easier to maintain and repair. Multi-cylinder engines require more expertise and frequent servicing.

6. Size and Weight

Single cylinder engines are compact and lightweight. Multi-cylinder engines are usually larger and heavier.

7. Applications

Single cylinder engines are best for motorcycles, generators, and small machines. Multi-cylinder engines power cars, trucks, and heavy machinery.

8. Noise and Vibration

Single cylinder engine tend to vibrate more and produce louder noise. Multi-cylinder engines offer smoother operation and reduced vibration.

Knowing the differences between single and multi-cylinder engines helps make better decisions. Consider the application, cost, and performance needs when selecting an engine.

Challenges and Limitations of Single Cylinder Engines

Single cylinder engines are efficient and cost-effective, but they come with certain limitations. Understanding these challenges can help users manage and operate them effectively.

1. Limited Power Output

Single cylinder engines produce less power than multi-cylinder engines. They are suited for low-power tasks like operating small machines or equipment.

2. Excessive Vibrations

These engines can vibrate more compared to multi-cylinder engines. The single piston often causes an imbalance, leading to more vibrations and noise during operation. This might cause discomfort over extended use.

3. Lower Smoothness

Due to single power strokes, the operation can be less smooth. There are more noticeable fluctuations in power output, especially at lower speeds.

4. Reduced Lifespan Under Heavy Use

The engine may wear out faster under heavy or constant use. Less robust construction makes them less suited for high-demand applications.

5. Limited Speed Capability

These engines may not perform well at higher RPMs. The single piston prevents sustained high-speed performance.

6. Cooling Issues

Single cylinder engines can heat up quickly with prolonged use. Overheating might lead to frequent breakdowns and higher maintenance needs.

7. Noise and Emissions Concerns

The sound generated by single cylinder engines can be loud. They may also produce higher emissions when operating inefficiently compared to some advanced multi-cylinder engines with lower emission rates.

8. Specific Usage Scenarios

Single cylinder engines are not ideal for applications requiring high power. Heavy vehicles, industrial machinery, and high-performance boats often require multi-cylinder engines instead.

Recognizing these limitations lets users select appropriate applications for single cylinder engine. Proper maintenance and usage can mitigate some challenges and ensure better performance for specific needs.

Leave a Reply