Introduction to Cylinder Configuration in Engines

Introduction to Cylinder Configuration in Engines

Engines are designed with cylinders as one of their key components. A highest cylinder engine is essentially a chamber where fuel combusts and converts energy into mechanical motion. The configuration and number of cylinders greatly influence the engine’s performance.

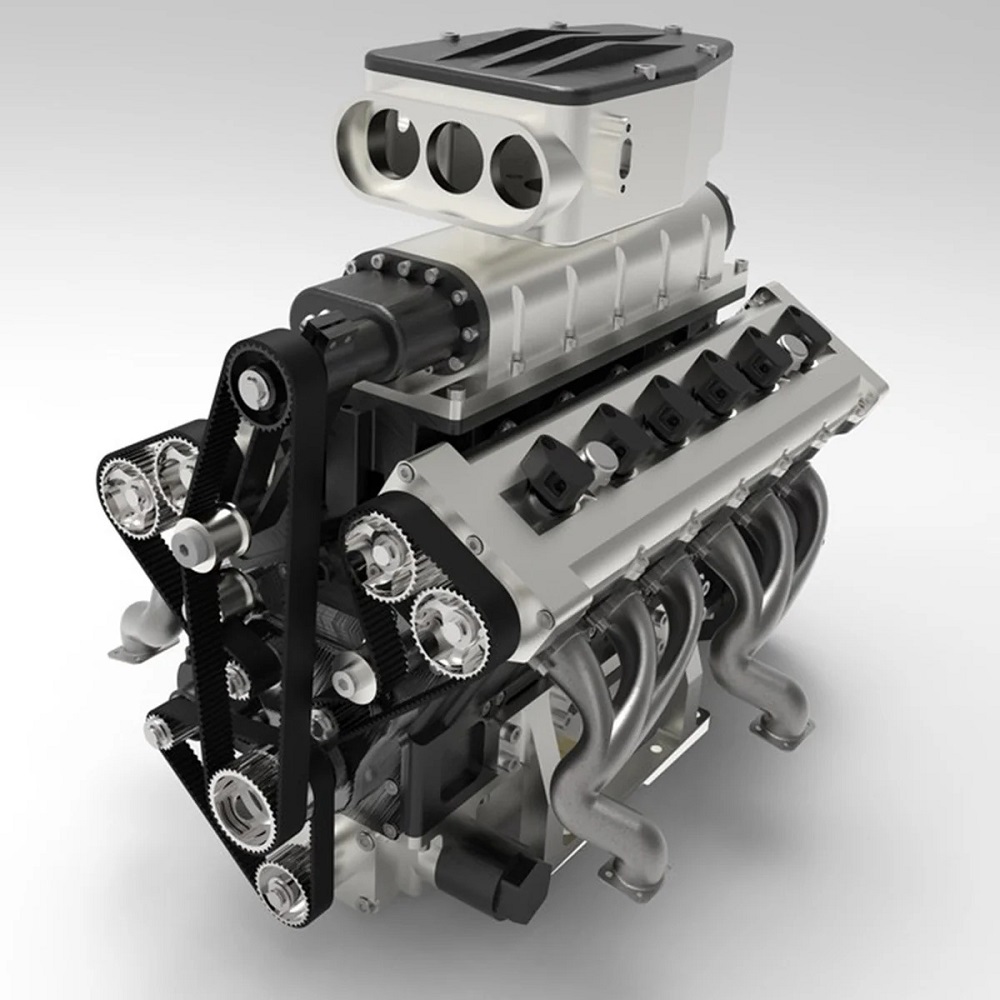

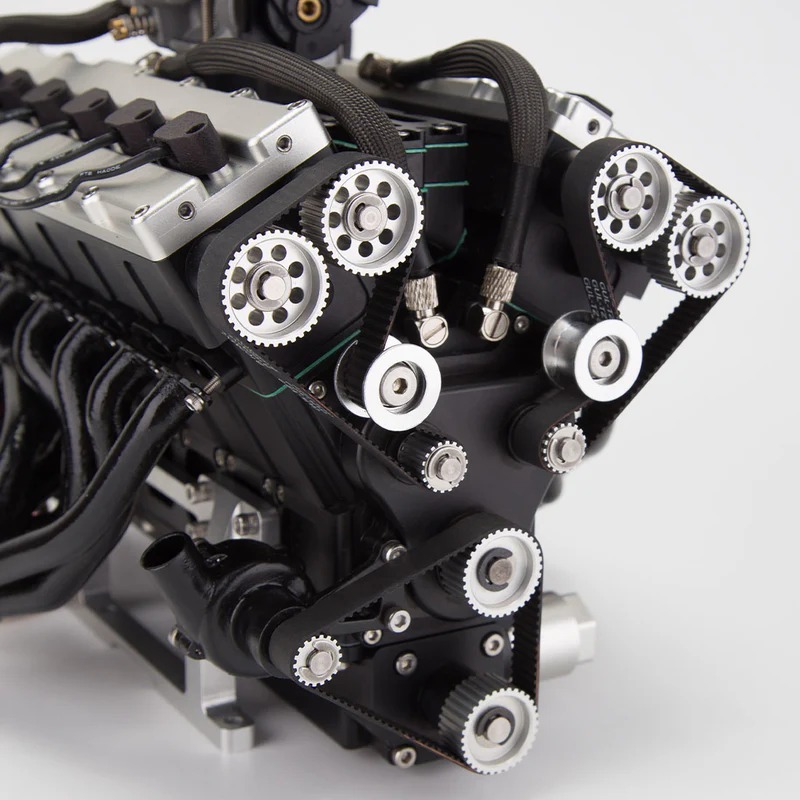

Cylinder configuration refers to the design and arrangement of cylinders within an engine. Common configurations include inline, V-shaped, flat, and W-shaped layouts. Each design has distinct characteristics, affecting power delivery, balance, and size.

Inline engines have cylinders arranged in a straight line. They are compact and widely used in small to medium-sized vehicles. V-shaped engines consist of two banks of cylinders placed at an angle to form a “V”. This configuration is popular for high-performance and luxury vehicles due to its compactness and power.

Flat engines, also known as boxer engines, have cylinders lying flat in pairs on opposite sides of the crankshaft. This design lowers the engine’s center of gravity, improving stability. W-shaped engines feature multiple cylinder banks arranged in a W formation, accommodating a higher cylinder count.

The number of cylinders determines the engine’s output, smoothness, and efficiency. Engines with the highest cylinder counts are known for delivering exceptional power and performance. Exploring these designs helps us understand the engineering complexity involved.

Why Cylinder Count Matters in Engine Design

The number of cylinders in an engine plays a crucial role in its performance and functionality. Cylinder count impacts power output, engine smoothness, and efficiency. Engineers carefully select the cylinder count based on the engine’s intended use.

Improved Power Output

More cylinders allow the engine to produce higher power levels. Each cylinder generates energy during combustion, so engines with more cylinders can handle larger amounts of fuel and air. This results in better performance, especially for vehicles requiring high speed or heavy load capacity.

Enhanced Smoothness

Higher cylinder counts contribute to smoother operation. Multiple cylinders spread out the engine’s workload, reducing vibrations. Engines like V12 or V16 models are known for their exceptionally smooth performance. This makes them ideal for luxury cars, where comfort is a priority.

Optimal Efficiency

Balancing cylinder count with engine design improves efficiency. With more cylinders, engines can run at lower revolutions while maintaining power output. This reduces stress on the engine, extending its lifespan. Efficiency is important for trucks, ships, and other large vehicles, where reliability matters.

Design Complexity

Although beneficial, high-cylinder engines come with challenges. More cylinders require intricate engineering and higher production costs. Larger engines also demand more space, which limits their use in compact vehicles. This makes these engines more common in specialized industries or high-performance machines.

Cylinder count is a key factor in engine design. It shapes power, smoothness, efficiency, and overall usability. Understanding its importance helps recognize the engineering balance needed for specific applications.

Historical Evolution of Multi-Cylinder Engines

Engine design has come a long way since the early days of single-cylinder engines. The move to multi-cylinder engines was driven by the need for more power, smoother operation, and better efficiency. Each stage of development added new complexities and innovations.

Early Development of Cylinder Technology

The first internal combustion engines featured only one cylinder. These engines were simple and compact but couldn’t produce much power. As vehicle and industrial demands grew, engineers realized the need for multiple cylinders to improve output and functionality.

By the late 19th century, two-cylinder engines became common. These offered an improvement in balance and power, but vibrations were still an issue. Manufacturers began experimenting with inline-cylinder designs to smooth performance.

Advancements in the 20th Century

In the early 20th century, engine designs advanced significantly. Four-cylinder engines became the standard for many automobiles. These engines delivered better power output and operated more smoothly. Inline-four engines were particularly popular due to their compact design and reliability.

Soon after, engineers introduced higher cylinder counts like six-cylinder and eight-cylinder configurations. V-engines, such as V8 models, became prominent for high-performance vehicles, offering robust power in a compact layout. Luxury cars began using V12 and V16 engines for improved smoothness and elite performance.

The late 20th century saw groundbreaking inventions with engines having over 12 cylinders. W-shaped designs emerged, allowing massive cylinder counts in limited space. These engines became famous for unparalleled performance, found in racing cars and high-powered industrial machines.

Modern Innovations

Today, engines with high cylinder counts continue to evolve. Advanced engineering has introduced materials and technologies, such as lightweight alloys and computer controls, to refine performance. Even engines with fewer cylinders now compete in efficiency, balancing power with eco-friendly advancements.

Multi-cylinder engine evolution mirrors engineering ingenuity. It demonstrates how innovation meets the growing need for performance across various industries.

Engines with the Highest Number of Cylinders Ever Built

Engines with the most cylinders are engineering marvels. They showcase human ingenuity and push performance limits. These engines are rare and typically used in specialized applications such as racing and luxury vehicles.

Engines with high cylinder counts are designed to generate immense power and smooth performance. They ensure a better balance and reduce engine vibrations significantly. Famous examples include V16 engines in luxury cars and V24 engines used in industrial applications. While impressive in power, these engines come with unique engineering challenges, including size constraints and high production costs.

Notable Examples of Engines with High Cylinder Counts

- Bugatti Chiron Engine (16 Cylinders): The Bugatti Chiron features a quad-turbocharged W16 engine. It produces unparalleled power and speeds exceeding 250 mph. This engine has become an icon of luxury and performance.

- Cadillac V16 (16 Cylinders): Introduced in the 1930s, the Cadillac V16 was one of the first luxury car engines with 16 cylinders. It showcased smooth performance and opulence, becoming a symbol of automotive excellence.

- Rolls-Royce Merlin Engine (12 Cylinders): This V12 engine powered aircraft like the Spitfire during World War II. It delivered massive power, playing a crucial role in aviation history.

- Napier Lion (24 Cylinders): The Napier Lion featured a unique “broad arrow” design, with three banks of cylinders. It was widely used in aircraft and racing vehicles, making it a groundbreaking innovation of its time.

Famous Brands and Their High-Cylinder Engine Models

- Bugatti: Known for their W16 engines, Bugatti creates some of the fastest hypercars in the world. The W16 engine is a technical masterpiece, offering both incredible speed and luxury.

- Rolls-Royce: Rolls-Royce has a history of producing elite vehicles with smooth V12 and V16 engines. Luxury and performance define their unmatched craftsmanship.

- Ferrari: Ferrari has built iconic V12 engines, which power their high-performance sports cars. These engines emphasize both speed and precision engineering.

- Lamborghini: Lamborghini specializes in V10 and V12 engines that deliver breathtaking power and thrilling drives. The brand is synonymous with performance and luxury.

Engines with high cylinder counts are rare but reflect the pinnacle of mechanical engineering. These designs have left a significant mark in the automotive and aviation industries.

Advantages and Challenges of High-Cylinder Engines

High-cylinder engines are remarkable for their power and performance but come with complexities. These engines have advantages and challenges that impact their applications and construction.

Advantages of High-Cylinder Engines

- Exceptional Power Output: High-cylinder engines produce immense power. The greater number of cylinders allows them to combust more fuel simultaneously, delivering impressive speeds and performance. This makes them ideal for high-performance vehicles and race cars.

- Smoother Operation: Engines with more cylinders operate smoothly, as the workload is distributed across multiple cylinders. This significantly reduces vibrations and ensures a better driving experience, especially in luxury cars.

- Improved Performance at Higher Speeds: These engines perform efficiently at higher speeds due to their ability to run at lower revolutions while maintaining power. This is a crucial advantage for both high-speed vehicles and certain industrial applications.

- Stability and Balance: The design of high-cylinder configurations, such as W16 or V12 engines, improves balance. Designs like the flat or boxer engine also lower the center of gravity, enhancing stability.

Challenges of High-Cylinder Engines

- Increased Engineering Complexity: High-cylinder engines demand advanced and precise engineering. Their intricate designs make them challenging to manufacture and maintain.

- High Production Costs: Developing and producing engines with the highest cylinder counts requires significant investment. This makes them expensive, suitable only for luxury cars and specialized machines.

- Size and Weight Constraints: These engines are larger and heavier than standard engines. They occupy more space, making them unsuitable for compact vehicles.

- Higher Fuel Consumption: Engines with many cylinders consume more fuel due to their greater power generation. This reduces fuel efficiency, increasing operational costs, particularly in commercial contexts.

Balancing Benefits and Shortcomings

Despite their challenges, high-cylinder engines continue to be utilized. Engineers strive to optimize their design and address their limitations. Advances in materials and technology help reduce weight and improve efficiency without sacrificing power or performance.

While high-cylinder engines may not suit regular vehicles, their advantages make them indispensable in specific applications requiring top-tier performance and reliability.

Applications of Multi-Cylinder Engines in Different Industries

Multi-cylinder engines are widely used across various industries due to their unique advantages. These engines offer high power, smooth performance, and reliability, which make them valuable for diverse applications.

Automotive Industry

Multi-cylinder engines drive innovation in cars and motorcycles. Luxury cars often use V12 or V16 engines for smooth and powerful operation. Sports cars benefit from high-cylinder engines like the Ferrari V12, ensuring top speeds and precise handling. Trucks and commercial vehicles use engines with more cylinders to handle heavy loads efficiently and reliably.

Aviation Industry

Aircraft depend on multi-cylinder engines for high power and reliability. Engines like Rolls-Royce Merlin or Napier Lion powered military and civilian aircraft during the mid-20th century. These engines provided the thrust required for higher altitudes and faster speeds, contributing to aviation advancements.

Marine Industry

Ships and submarines need high-cylinder engines for sustainable operation. These engines provide the torque required to push large vessels through water. Efficiency and reliability are crucial in marine engines, making multi-cylinder configurations favorable.

Power Generation Industry

Power plants use multi-cylinder engines to generate electricity. These engines provide consistent and efficient power to grids or remote industrial facilities. Their ability to run for long durations without failing is especially important.

Industrial Machinery

High-cylinder engines are integral to heavy machinery, such as excavators, cranes, and generators. They deliver the strength needed to operate large-scale industrial equipment. Their durability ensures consistent performance in demanding environments.

Multi-cylinder engines play a crucial role in modern industries. They balance power, efficiency, and reliability to meet specific requirements. Engineers continue refining these engines for new innovations and applications.

The Future of High-Cylinder Engines in Modern Engineering

High-cylinder engines showcase exceptional power and precision. Their future depends on innovation and solving challenges.

Advancements in Technology

- Lightweight Materials: Engineers use lightweight alloys to reduce engine weight and improve efficiency.

- Computerized Control Systems: Advanced controls increase precision, optimize fuel use, and enhance overall performance.

- Eco-Friendly Innovations: Green technologies aim to minimize emissions and maximize fuel efficiency in high-cylinder configurations.

Industry-Specific Applications

- High-Performance Vehicles: Luxury and sports cars will continue using advanced high-cylinder engines for speed and comfort.

- Aviation: Engines with many cylinders will play a crucial role in propelling modern aircraft.

- Marine and Industrial Machinery: Large vessels and heavy-duty machines will rely on refined, multi-cylinder engines for durability and output.

Challenges Ahead

- Balancing Performance and Efficiency: Engineers must create engines that deliver power without excessive fuel consumption.

- Production Costs: High engineering complexity demands cost-effective manufacturing solutions.

- Competing Technologies: Electric engines and hybrid designs pose a strong challenge to traditional cylinder setups.

Future Possibilities

- Innovative Configurations: Designers may explore unconventional cylinder arrangements for better performance.

- Integration with AI: Artificial intelligence can optimize engine operation for specific applications.

- Global Sustainability Goals: Future engines must align with environmental regulations and green energy initiatives.

The future of high-cylinder engines will depend on their adaptability. Engineers must balance power, efficiency, and environmental concerns to drive innovation forward.

Conclusion

The Enduring Appeal of Multi-Cylinder Engines

Highest cylinder engine will continue to captivate automotive enthusiasts for their performance and engineering innovation. The power and thrill offered by multi-cylinder configurations make them a staple in the performance vehicle segment. As technology advances, these engines are likely to undergo further refinements, allowing them to meet modern performance and environmental standards.

The Balance of Performance and Efficiency

As the automotive landscape evolves, finding a balance between performance and fuel efficiency is increasingly important. High-cylinder engines provide exhilarating experiences but must adapt to changing consumer preferences and regulations. Innovations aimed at enhancing efficiency while maintaining performance will be central to the future of multi-cylinder engines.

Embracing the Journey Ahead

As we look toward the future, the journey of multi-cylinder performance continues to unfold. For enthusiasts and casual drivers alike, understanding the significance of high-cylinder engines is essential. These engines represent the culmination of engineering excellence and the desire for speed. Embrace the excitement and innovation that high-cylinder engines bring to the automotive world as the future takes shape, and remember that while engines evolve, the thrill of the ride remains timeless.

Leave a Reply