In the realm of material handling, forklifts stand as indispensable tools, revolutionizing the way we transport and manage goods. These powerful machines, often referred to as lift trucks, are ubiquitous in warehouses, factories, and construction sites, enabling efficient movement and lifting of heavy loads. This guide delves into the world of forklifts, exploring their history, types, applications, safety considerations, maintenance practices, and the factors influencing their selection to help you understand and operate these remarkable machines effectively.

Introduction to Forklifts: A Brief History

The story of forklifts began in the early 1900s, with the invention of lifting devices that attached to automobiles. Over time, these primitive machines evolved into specialized forklifts, designed specifically for material handling tasks. The introduction of hydraulics in the 1920s further revolutionized forklift design, providing greater lifting capacity and maneuverability. Today, forklifts come in various configurations and power sources, catering to a wide range of material handling needs.

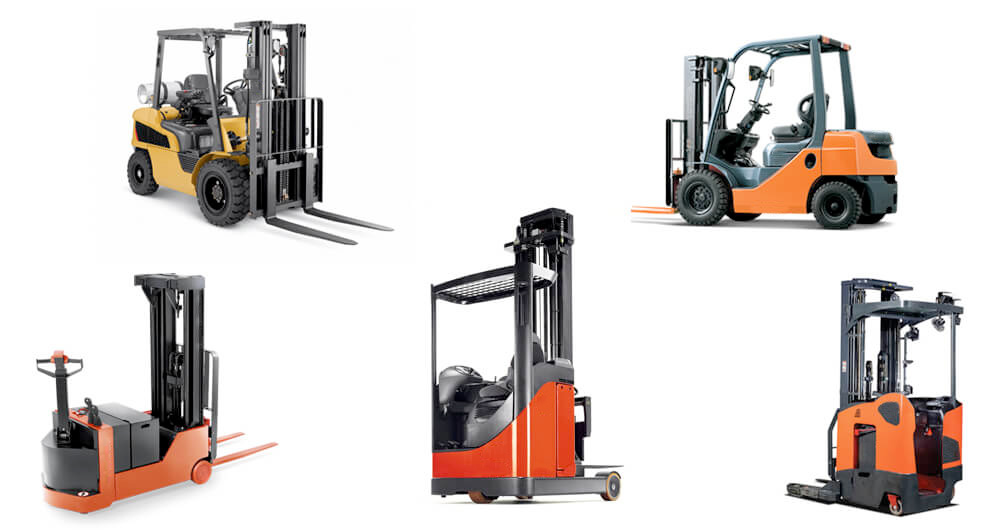

The world of forklifts encompasses a diverse array of types, each tailored to specific applications and environments. Here are some of the most common forklift categories:

-

IC Forklifts (Internal Combustion Forklifts): Powered by internal combustion engines, such as diesel or gasoline, IC forklifts offer exceptional power and durability, making them ideal for outdoor use and heavy-duty applications.

-

Electric Forklifts: Utilizing electric motors and batteries, electric forklifts provide cleaner, quieter operation and are well-suited for indoor environments where emissions and noise are concerns.

-

Rough Terrain Forklifts: Designed to handle uneven and challenging surfaces, rough terrain forklifts feature large tires, high ground clearance, and four-wheel drive, making them suitable for construction sites and outdoor work.

-

Narrow Aisle Forklifts: These specialized forklifts operate efficiently in narrow aisles, maximizing storage space in warehouses and distribution centers.

Applications of Forklifts: A World of Material Handling Possibilities

Forklifts find applications in a vast array of industries, from manufacturing and warehousing to construction and retail. Their primary function involves lifting, transporting, and stacking goods, but their versatility extends beyond these core tasks. Here are some examples of how forklifts are utilized:

-

Loading and Unloading Trucks: Forklifts efficiently transfer goods between trucks and storage areas.

-

Pallet Handling: Forklifts are designed to lift, move, and stack pallets, the standard unit of load in many industries.

-

Order Picking: In warehouses, forklifts are used to pick and retrieve specific items from shelves for order fulfillment.

-

High-Level Storage: Forklifts with extended masts can reach high shelves for storing and retrieving goods.

Safety Considerations for Forklift Operation

The safe operation of forklifts is paramount to prevent accidents and injuries. Here are some essential safety guidelines:

-

Proper Training: Operators must receive adequate training and certification to operate forklifts safely.

-

Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety vests, hard hats, and steel-toed boots.

-

Pre-Operation Inspection: Before each use, inspect the forklift for any signs of damage or malfunction.

-

Load Stability: Ensure loads are properly balanced and secured to prevent tipping.

-

Awareness of Surroundings: Be aware of pedestrians and other vehicles while operating the forklift.

-

Speed Limits: Adhere to speed limits and avoid reckless driving.

Forklift Maintenance Practices: Ensuring Optimal Performance

Regular maintenance is crucial to keep forklifts operating safely and efficiently. Here are some key maintenance practices:

-

Routine Checks: Regularly check fluid levels, tire pressure, and brake performance.

-

Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule, including oil changes and tune-ups.

-

Preventive Maintenance: Inspect for potential issues and address them promptly to prevent breakdowns.

-

Record Keeping: Maintain records of maintenance activities and inspections.

Factors Influencing Forklift Selection: Choosing the Right Machine

Selecting the right forklift for your specific needs requires careful consideration of several factors:

-

Load Capacity: Determine the maximum weight and size of loads you need to handle.

-

Lifting Height: Consider the height at which you need to lift and stack goods.

-

Operating Environment: Evaluate the type of terrain and work environment, whether indoor or outdoor.

-

Power Source: Choose between IC or electric forklifts based on your emissions and noise requirements.

-

Special Features: Consider additional features like side shifters, rotators, or attachments for specific tasks.

The Future of Forklifts: Innovation and Automation

The future of forklifts is brimming with innovation and automation. Here are some emerging trends shaping the landscape:

-

Lithium-Ion Battery Technology: Advancements in lithium-ion battery technology are paving the way for longer runtime and faster charging times in electric forklifts.

-

Autonomous Forklifts: Self-driving forklifts are being developed to automate repetitive tasks in warehouses, improving efficiency and safety.

-

Telepresence Operation: Remotely operated forklifts allow operators to control the machine from a safe distance, especially in hazardous environments.

-

Advanced Safety Features: Forklifts are being equipped with additional safety features like object detection and collision avoidance systems to minimize accidents.

The Impact of Forklifts on Our Lives

The impact of forklifts on our daily lives is profound, though often unseen. From the clothes we wear to the food we eat, forklifts play a crucial role in the efficient movement of goods throughout the supply chain. By ensuring the safe and efficient operation of these remarkable machines, we contribute to a well-functioning economy and a steady flow of goods that fuel our modern way of life.

Choosing the Right Forklift Partner

Selecting the right forklift supplier or rental company is crucial for your operation’s success. Here are some factors to consider when making your choice:

-

Reputation: Choose a reputable company with a proven track record of providing reliable forklifts and excellent customer service.

-

Fleet Selection: Ensure the company offers a wide range of forklift types to cater to your specific needs.

-

Maintenance and Repair Services: Opt for a company that provides comprehensive maintenance and repair services to keep your forklifts running smoothly.

-

Training and Support: Look for a company that offers forklift operator training and ongoing support to ensure your team’s safety and productivity.

By following these guidelines, you can choose a reliable forklift partner that will help you optimize your material handling operations.

In Conclusion

Forklifts are the backbone of modern material handling. Understanding their history, types, applications, and operational considerations empowers you to leverage these remarkable machines effectively. As technology continues to evolve, forklifts will become even more sophisticated and efficient, playing an ever-increasing role in shaping the future of our supply chains. So, whether you’re working in a warehouse, on a construction site, or in any industry that relies on the movement of goods, appreciate the power and versatility of the forklift – a true powerhouse in the world of material handling.

Leave a Reply