In the intricate world of automotive powertrains, drive clutches stand as unsung heroes, silently orchestrating the transfer of power from the engine to the wheels. While various clutch designs exist, belt-driven clutches have garnered significant attention in recent years, captivating the automotive realm with their simplicity, efficiency, and smooth operation. Whether you’re a seasoned mechanic or an automotive enthusiast eager to expand your knowledge base, understanding the intricacies of drive clutches with belts is paramount for maintaining optimal vehicle performance.

I. Introduction

A. Overview of drive clutches and their significance in automotive powertrains:

Drive clutches, also known as starting clutches, are indispensable components of automotive powertrains, serving as the critical link between the engine and the transmission. They facilitate the smooth engagement and disengagement of power transfer, enabling seamless gear changes and preventing abrupt jolts during vehicle operation.

B. Introduction to belt-driven clutches and their advantages:

Belt-driven clutches have emerged as a popular choice for automotive applications due to their inherent advantages. These clutches employ a flexible belt to transmit power from the engine crankshaft to the clutch drum, offering a quieter, smoother, and more durable alternative to traditional friction plate clutches.

C. Key features and considerations when selecting a drive clutch with a belt:

When choosing a drive clutch with a belt, several factors should be carefully considered. The type of belt, whether cogged or V-belt, plays a significant role in power transmission and durability. Additionally, the clutch’s torque capacity, material composition, and compatibility with the specific vehicle are crucial aspects to evaluate.

II. Types of belt-driven drive clutches

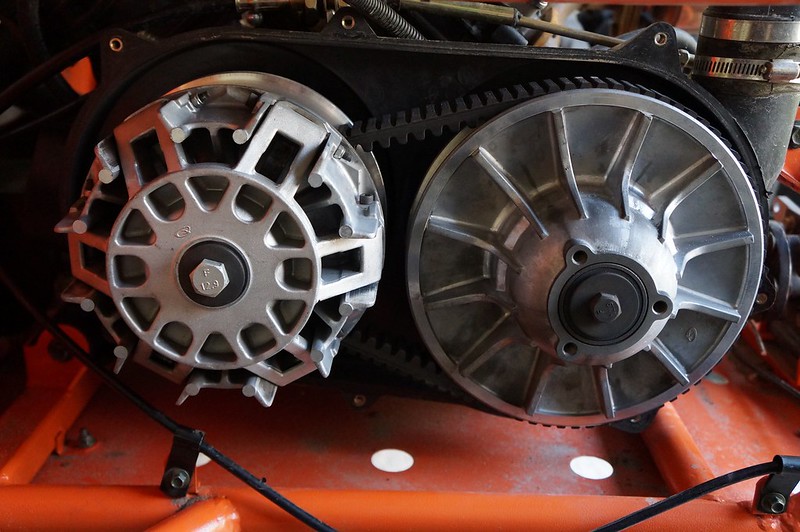

A. Cogged belts:

Cogged belts feature interlocking teeth that provide positive engagement and high torque capacity, making them suitable for high-performance applications. These belts offer superior durability and resistance to slip under heavy loads.

B. V-belts:

V-belts, also known as wedge belts, utilize a trapezoidal profile to optimize power transmission and reduce friction. They are commonly used in lighter-duty applications and offer a smooth, quiet operation.

III. How a belt-driven drive clutch works

A. Transmission of power from the engine:

The engine’s crankshaft rotates a pulley attached to the clutch housing. This rotation is transferred to the belt, which then drives the clutch drum connected to the transmission.

B. Engagement and disengagement mechanism:

Upon engaging the clutch, a hydraulic or mechanical actuator applies pressure to the clutch pressure plate, forcing the belt against the clutch drum. This frictional contact transmits power to the transmission.

C. Smooth and controlled power transfer:

The flexible belt allows for smooth and controlled power transfer, minimizing jerking or abrupt engagement, which can enhance driving comfort and protect drivetrain components.

IV. Benefits of using a belt-driven drive clutch

A. Smooth and quiet operation:

Belt-driven clutches offer a noticeably smoother and quieter operation compared to traditional friction plate clutches. This is due to the absence of metal-to-metal contact and the inherent flexibility of the belt.

B. Reduced wear and tear:

The use of a belt instead of friction plates significantly reduces wear and tear, extending the clutch’s lifespan and minimizing maintenance requirements. The belt is the primary wear component, and it can be easily replaced when necessary.

C. Improved durability:

Belt-driven clutches are generally considered more durable than friction plate clutches, particularly in high-performance applications. The belt’s resistance to heat and fatigue contributes to its extended service life.

D. Dampening of torsional vibrations:

The flexible belt effectively dampens torsional vibrations from the engine, preventing them from being transmitted to the drivetrain. This contributes to a smoother and more refined driving experience.

V. Applications of belt-driven drive clutches

A. Automobiles:

Belt-driven clutches are increasingly being used in automobiles, particularly in smaller, fuel-efficient vehicles. Their smooth operation and reduced wear make them well-suited for modern driving conditions.

B. Motorcycles:

Belt-driven clutches are also common in motorcycles, especially in cruiser and touring models. Their quietness and durability are highly valued by motorcycle enthusiasts.

C. ATVs and UTVs:

All-terrain vehicles (ATVs) and utility terrain vehicles (UTVs) often employ belt-driven clutches due to their ability to handle high torque loads and provide smooth power delivery in challenging terrain.

D. Industrial applications:

Belt-driven clutches are also used in various industrial applications, such as power tools, agricultural machinery, and conveyor systems. Their versatility and durability make them suitable for a wide range of industrial applications.

VI. Maintenance and care for belt-driven drive clutches

A. Regular inspection:

Inspect the belt for signs of wear or damage, such as cracks, fraying, or glazing. Check for proper belt tension and ensure the clutch housing is free of debris or contamination. A worn or damaged belt can lead to slipping, reduced power transfer, and premature clutch failure.

B. Belt replacement:

When the belt shows signs of wear or reaches its recommended service life, it should be replaced promptly. Replacing the belt is a relatively straightforward process for most vehicles and can often be done at home with the proper tools and a workshop manual.

C. Avoiding clutch abuse:

To maximize the lifespan of your belt-driven drive clutch, avoid practices that contribute to excessive wear and tear. This includes practices like aggressive clutch engagement, frequent hard launches, and overloading the vehicle.

VII. Troubleshooting common belt-driven drive clutch problems

A. Slipping clutch:

A slipping clutch manifests as a lack of power transfer despite high engine revs. This can be caused by a worn or damaged belt, improper belt tension, or a faulty clutch pressure plate.

B. Grinding noises:

Grinding noises during clutch operation can indicate worn clutch components, such as the belt or clutch bearings. In severe cases, it may signify internal damage to the clutch housing.

C. Difficulty engaging or disengaging the clutch:

Difficulty engaging or disengaging the clutch can be caused by a faulty hydraulic or mechanical actuator, a malfunctioning clutch release bearing, or air trapped in the clutch hydraulic system (if applicable).

VIII. Upgrading a belt-driven drive clutch

A. Performance considerations:

For performance-oriented applications, enthusiasts may consider upgrading their belt-driven drive clutch. Upgraded clutches may feature high-performance belts with improved strength and heat resistance. Additionally, stronger clutch springs can be employed to handle increased torque loads.

B. Aftermarket options:

A wide range of aftermarket belt-driven drive clutch components are available for various vehicles. When choosing upgrades, ensure compatibility with your specific vehicle and consult a qualified mechanic if necessary.

IX. Conclusion

Mastering the intricacies of drive clutches with belts empowers you to maintain optimal performance and extend the lifespan of your vehicle’s drivetrain. By understanding their operation, benefits, and maintenance requirements, you can make informed decisions about clutch care and potential upgrades. Whether you’re a seasoned mechanic or an automotive aficionado, appreciating the role of belt-driven drive clutches adds another layer of understanding to the fascinating world of automotive technology.

Leave a Reply